ADDere Standard System

ADDere's compact solution to additive manufacturing

The ADDere Standard System is housed in a compact portable enclosure with everything required for 3D metal printing on-demand parts. The Standard System is a laser-wire additive manufacturing (LWAM) system that utilizes a highly accurate 6-axis industrial robot that is paired with a 2-axis coordinated motion workpiece positioner.

This system is capable of building components at near net shape from a number of common or specialty metal-based materials such as stainless steel or Inconel. An optional inert argon gas environment extends the capabilities of this system to build parts out of Titanium and a wide range of superalloys. The 4-6 kW laser combined with a 500-amp hot wire delivery package provides plentiful power for depositing material at a large scale. All of these only require 100 KVA to operate making the system easy to set up in different locations.

ADDere uses a real-time sensor system that is key to ADDere’s dimensional performance and quality of metal disposition. With closed-loop sensing and control the ADDere’s systems can offer some of the most consistent builds, with excellent metallurgical qualities and near net shaped results that reduce the amount of finishing required for the final product.

Along with the physical system, ADDere also provides the software that drives the entire additive manufacturing process. The ADDere Runtime Software controls the build height and width, the energy density control, head mapping and inter-pass print control, and the deposition rate control.

Standard System Specifications

| Motion Device | 6-Axis Robotic Motion System |

| Build Part Size (L x W x H) |

1m x 1m x 1m working envelope |

| Built Part Max Weight | 400 kg including fixturing |

| Laser Power | 4-20kW Laser |

| Wall/Layer Size | Typical 5-6mm pass width and 1-2mm layer height |

| Sensor System | Real-time, Closed-loop fixed optic with options for coaxial or dithering spot |

| Enclosure | Full laser safety enclosure with options for an inert gas environment. Unitized base and separate utility base for easy transport. |

| Material Delivery | 500-amp hot wire system with power source tracked by closed-loop feedback control |

If you have any additional questions about the ADDere Systems or which system best fits your additive manufacturing applications, please feel free to reach out to us.

do you want to learn more about ADDere's products and services?

From common metals to superalloys

Materials ADDere Prints

Best-in-class Printing Performance

Sample Parts

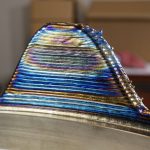

Turbine Blade

Highly complex stainless steel part that stands 5ft 11in or 1800 layers tall with a height variant of >0.5mm. Learn more ❯

Deposition rate: 4.5 lbs./h

Build time: 30 hours

Material: Duplex Stainless Steel

Equipment used: ADDere Custom System

Rocket Thrust Chamber Assembly

Highly complex seamless stainless steel part that stands 42in tall with a wall thickness of 3mm. Learn More ❯

Deposition rate: 4 lbs./h

Build time: 20 hours

Material: Duplex Stainless Steel

Equipment used: ADDere Custom System

Duplex Stainless Steel Build Plate

Building upon an already finished build plate.

Deposition rate: 23 lbs./h

Build time: 3+ days

Material: Duplex Stainless Steel

Equipment used: ADDere Custom System

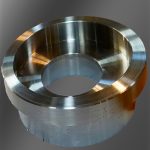

Gear

A solid gear made entirely from stainless steel.

Deposition rate: 20 lbs./h

Build time: 10 hours

Material: Stainless Steel

Equipment used: ADDere Custom System

Freeform Design

A demonstration part with a hollow 6mm wall thickness.

Deposition rate: 4.5 lbs./h

Build time: 20 hours

Material: Stainless Steel

Equipment used: ADDere Custom System

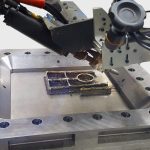

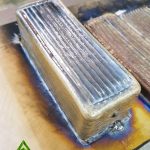

Mold Form

Three-hour 3D laser-wire additive build time reduced subtractive processes. The carbon Steel metal printing process allowed customers to move into production faster and more cost-effectively than conventional processes.

Deposition rate: 6 lbs./h

Build time: 3 hours

Material: Carbon Steel

Equipment used: ADDere Standard System

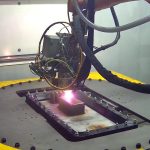

Propeller

Thin-walled metal components are 3D printed onto the existing part. The ADDere additive manufacturing process allows printing onto components built through other means.

Deposition rate: 3 lbs./h

Build time: 4 hours

Material: Carbon Steel

Equipment used: ADDere Standard System

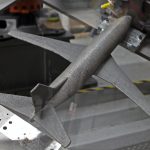

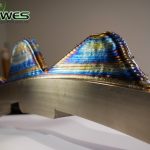

Wing Spar

High-complexity 3D print in titanium. Cross-section aspects of 3D printing reduce construction times and make for a stronger overall part.

Deposition rate: 6 lbs./h

Build time: 1 hour

Material: Titanium Ti64

Equipment used: ADDere Custom System

Cross-section Build

High-complexity 3D print in titanium. Inner detail work makes for ideal additive printing.

Deposition rate: 6 lbs./h

Build time: 1 hour

Material: Titanium Ti64

Equipment used: ADDere Custom System

Titanium Box

High-complexity 3D print in titanium. Inner detail work makes for ideal additive printing.

Deposition rate: 6 lbs./h

Buidt time: 3 hours

Material: Titanium Ti64

Equipment used: ADDere Custom System

Titanium Solid Bar

A solid bar made entirely from Titanium.

Deposition rate: 7 lbs./h

Build time: 6 hours

Material: Titanium Ti64

Equipment used: ADDere Custom System

Part Cladding

Evaluation of the part cladding process.

Deposition rate: 5 lbs./h

Build time: 2 hours

Material: Titanium Ti64

Equipment used: ADDere Custom System