How the ADDere Process Works

The ADDere Manufacturing Process

The ADDere laser-wire additive manufacturing (LWAM) system prints casting grade large-scale metal parts layer-by-layer in three dimensions. ADDere’s systems are controlled by a suite of high-speed, real-time, closed-loop sensors and purpose-built control software built around an industrial robot’s movement system. As with more common 3D printers that work in thermoplastics, ADDere simply sources the part construction and design from standard 3D modelled CAD drawings to produce the final near net shape metal-based part.

The ADDere laser-wire additive manufacturing (LWAM) system prints casting grade large-scale metal parts layer-by-layer in three dimensions. ADDere’s systems are controlled by a suite of high-speed, real-time, closed-loop sensors and purpose-built control software built around an industrial robot’s movement system. As with more common 3D printers that work in thermoplastics, ADDere simply sources the part construction and design from standard 3D modelled CAD drawings to produce the final near net shape metal-based part. The Build Volume

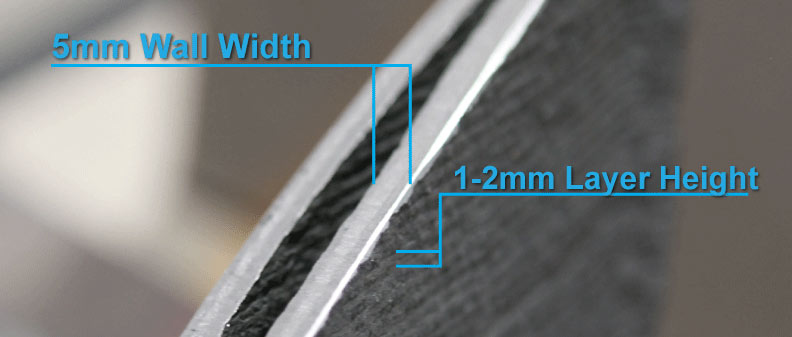

ADDere’s additive manufacturing systems have a build volume that starts at around 15 cm (6 inches) cubed and scales upwards to meters for custom large-scale productions. To achieve the best results in speed and efficiency builds typically have a layer height of around 1-2mm, and a wall thickness starting at about 5mm.

The Components of ADDere

The ADDere additive manufacturing process is built around four main components: the laser heat source, the material delivery system, the motion control system and the ADDere Runtime Software control system.

The Laser Heat Source

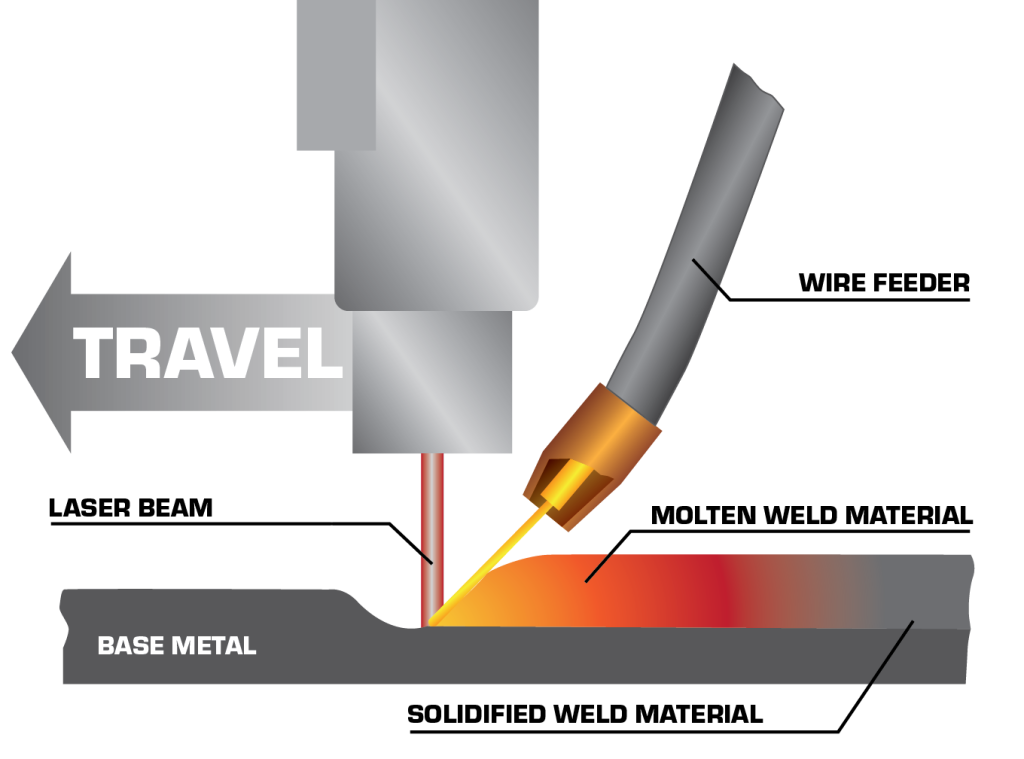

The ADDere laser-wire system utilizes a precise application of intense heat by a 4-30kW diode laser at the point of delivery. The intensity and accuracy of the laser are continuously monitored and controlled, minimizing the amount of wear on the build. As the material delivery system feeds the metal wire to the point of delivery, the wire is electrically pre-heated and softened into a more malleable state. ADDere’s laser wire system can function at room temperature and does not require a vacuum environment, however, some exotic metals do require an argon gas atmosphere to produce consistent builds.

The Material Delivery System

ADDere’s material delivery system uses a precisely controlled and easy to work with wire delivery system that has multiple wire drive units that work together, in a push-pull operation, to provide the correct amount of wire needed at the point of contact. Using a secondary laser, ADDere’s material delivery system tracks the progress of the build, and makes adjustments to the delivery of the material as needed. The ADDere additive manufacturing process builds up the components from interchangeable spools of metal wire. The metal wire can be of any weldable form of metal, such as carbon steel, stainless steel, Inconel, Hastelloy, Invar, Titanium and many more.

The Motion Control System

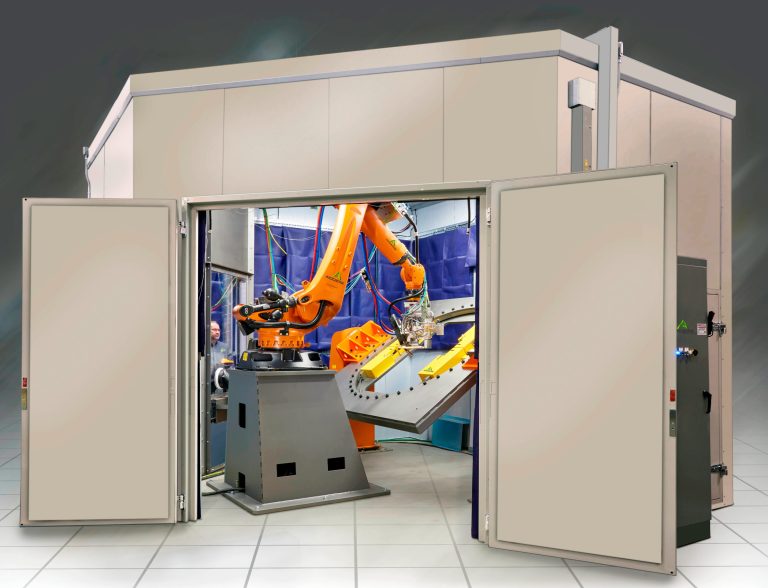

ADDere uses an industrial-size 6-axis robot as the primary controller of the delivery system and is controlled by a real-time closed-loop process controller. The motion system utilizes an additional 2-axis coordinated motion workpiece positioner, which would allow for building more complex parts that have over-hanging features. A track or gantry system can also be used to print less complex parts but on a much larger scale. This additional axis can be easily implemented into the robot controller to manipulate the substrate and increase the travel range of the robot.

The Runtime Software

ADDere’s Additive Manufacturing process is completely controlled by ADDere’s closed-loop runtime software. ADDere’s software controls the heat and material deposition, providing best-in-class metallurgical qualities that minimize build distortion, porosity and impurities. Each 3D printed layer is recorded in real-time for sensory feedback and system build adjustments to ensure a consistent build. ADDere’s Runtime Software brings the next level of quality and consistency to 3D metal printing.

Can ADDere help your business?

The demand for exotic superalloy metals has been rapidly growing in the aerospace, defense, marine, oil & gas and petrochemical industries. These exotic metals are inherently expensive and difficult to machine or cast on a large scale. However, with ADDere’s LWAM process, individual parts can be manufactured faster and more cost-effectively by eliminating material waste that would otherwise result from traditional machining or casting.

If ADDere’s high-quality large-scale metal additive manufacturing process sounds like something that your firm would benefit from, whether it’s in aerospace, defense, oil & gas or any other industry, contact us today. The ADDere laser-wire additive manufacturing process can produce large-scale builds in a wide range of sizes and materials near net shape to fit all your manufacturing needs.

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Where the ADDere Additive Process Excels Over Metal Casting

Metal casting and additive manufacturing are the two most common methods of producing large-scale metal parts. Metal casting involves pouring molten metal into a mold

Trends and Future Prospects in Large-Scale Metal 3D Printing

Industrial Metal additive manufacturing is not a new technology or concept. Still, it has gained significant momentum in recent years in many industries, thanks to

The Opportunities of Additive Manufacturing for Sustainable Development & Circular Economy

ADDere’s additive manufacturing process contributes to sustainable development and a circular economy by reducing material waste, energy consumption, greenhouse gas emissions and transportation costs. It

How Additive Manufacturing Can Reduce Production Lead Times

Production lead time is a critical variable for companies that rely on production and manufacturing processes to produce goods. In traditional manufacturing processes, it can

ADDere Provides GKN Aerospace with the Industry’s Largest Additive Manufacturing System

Building large-scale titanium parts for aerospace applications requires the largest metal 3D printer available. Because of the demanding nature of aerospace components and their previous

Unlocking Synergies: How Hybrid Manufacturing Can Enhance Additive Manufacturing

Additive manufacturing is a revolutionary technology that enables the creation of complex geometries and customized parts. However, metal additive parts have some limitations, such as