Titanium in the Aerospace Industry

Why Titanium is used in Aerospace

Titanium is one of the most durable and expensive metals in the world today. The rarity of the element and its high cost of production makes it an expensive metal, but despite the high price tags, the aircraft manufacturing industry is still looking for the material to build their products as it offers a spectacular strength-to-weight ratio and thermodynamic properties. Titanium-based alloys can become products that will be used to build a number of aerospace components used in engines, airframes and mechanical components.

More than a century after its first discovery, scientists found a fit in the commercial aerospace and defense industries. Since then, many firms are using the element to produce alloys that will be used to create a variety of aircraft components. Engineers point to the materials’ higher weight-to-strength ratio than steel and aluminum, Titanium’s performance when exposed to high temperatures, and the material’s ability to resist corrosion making it a valuable metal for making airplanes.

Where Titanium is used in Aerospace

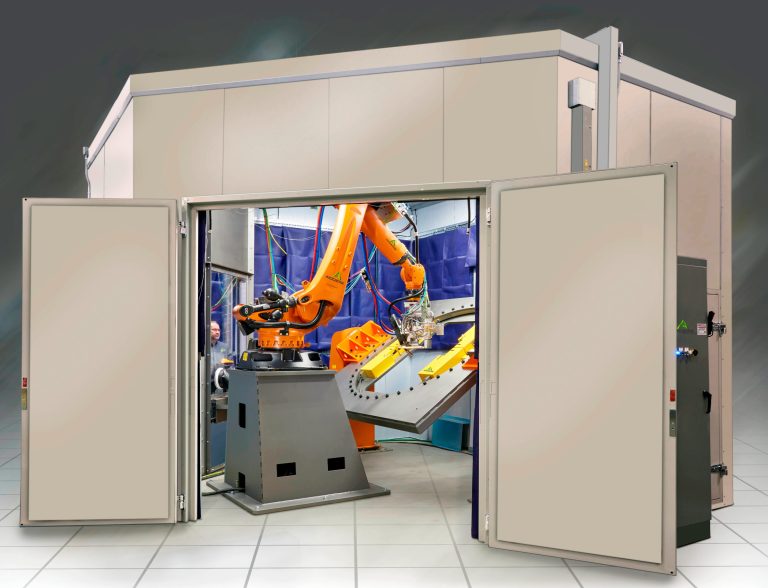

The aerospace industry is also spending large budgets on developing manufacturing processes that try to make the building of titanium components more cost-effective. While today’s methods of either casting or machining titanium alloys from billet are what’s considered most effective, new technologies like laser wire additive manufacturing found in the ADDere process can reduce production costs and development time by printing titanium alloys at scale and reduce costly titanium machining time. As production prices come down, the unique characteristics of the material become more and more tantalizing.

Fuel is a limited resource and aircraft consume a lot of it when they fly. To help reduce the energy costs of flight, many aircraft manufacturers are resorting to using Titanium to build fuel-efficient airplanes. The weight-to-strength ratio of Titanium makes it the best material of choice when building an airplane’s turbine engine power plants, airframe structural elements and other mechanical elements. Titanium alloys are lighter than other metals, and it also has greater durability.

Titanium is able to resist high temperatures and corrosion, especially when it makes contact with CFRPs, also known as carbon fiber-reinforced polymers. When the airplane takes off or lands, the friction that it creates when reaching for the runway is what generates extreme heat. Using Titanium, the damages incurred from these events can be lowered. Engine components, landing gear, and airframes of aircraft are now manufactured more and more out of Titanium. Airline companies are increasing the use of these advanced materials as they are more reliable compared to other metals.

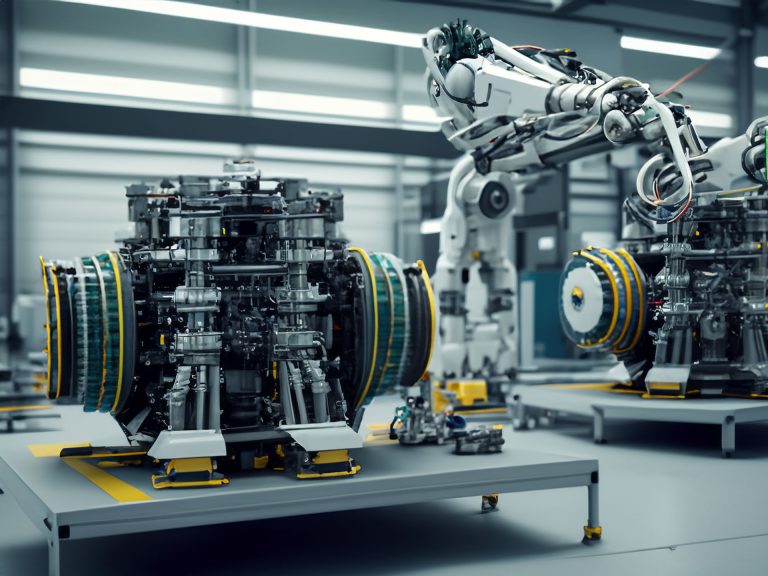

Aside from the aircraft components and airframes, Titanium is also used to build modern turbine engines. Many aircraft manufacturers have implemented the use of Titanium in creating engines due to their low weight and higher strength. Airplanes that use engines that are made from Titanium have better flight performance compared to other airplanes that are made from other metal alloys. Titanium alloys can also withstand extreme temperatures found in today’s high-efficiency turbine power plants. This material characteristic is pushing more airplane manufacturers to expand their use of Titanium, and discover where it can be applied further.

ADDere’s additive manufacturing can streamline the development and production process of large-scale components made from titanium. Contact us today and see if your manufacturing operations can benefit from ADDere’s additive manufacturing with titanium.

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Where the ADDere Additive Process Excels Over Metal Casting

Metal casting and additive manufacturing are the two most common methods of producing large-scale metal parts. Metal casting involves pouring molten metal into a mold

Trends and Future Prospects in Large-Scale Metal 3D Printing

Industrial Metal additive manufacturing is not a new technology or concept. Still, it has gained significant momentum in recent years in many industries, thanks to

The Opportunities of Additive Manufacturing for Sustainable Development & Circular Economy

ADDere’s additive manufacturing process contributes to sustainable development and a circular economy by reducing material waste, energy consumption, greenhouse gas emissions and transportation costs. It

How Additive Manufacturing Can Reduce Production Lead Times

Production lead time is a critical variable for companies that rely on production and manufacturing processes to produce goods. In traditional manufacturing processes, it can

ADDere Provides GKN Aerospace with the Industry’s Largest Additive Manufacturing System

Building large-scale titanium parts for aerospace applications requires the largest metal 3D printer available. Because of the demanding nature of aerospace components and their previous

Unlocking Synergies: How Hybrid Manufacturing Can Enhance Additive Manufacturing

Additive manufacturing is a revolutionary technology that enables the creation of complex geometries and customized parts. However, metal additive parts have some limitations, such as