Inconel

Let ADDere manufacture your parts with Inconel

Inconel® encompasses a particular group of nickel alloys or nickel-chromium alloys. Inconel alloys are durable, corrosion-resistant, rust-resistant and very sturdy. Inconel is a Special Metals registered trademark, with the name referring to certain superalloys of nickel and chromium. These alloys are produced with differing grades, ranging in a limitless number of sizes and shapes. Inconel can come in grades 601, 625, 718 and dozens more.

The various grades of Inconel have differing amounts of certain metals, and these different configurations mean that each alloy’s properties will slightly differ. The majority of Inconel grades contain both nickel and chromium, with many of these alloys also containing much smaller amounts of materials such as aluminum, iron, tin and cobalt. ADDere’s additive system has descriptive material reference charts and other information that outlines the chemical makeup present in each of ADDere’s metal 3D printing system Inconel alloys.

Common Variations of Inconel

Variation 601

The 601 variations of this metal are composed of a nickel-chromium base. It is known to be able to keep its structural integrity even after it has been exposed to extreme conditions for prolonged periods of time. It can resist oxidation up to 2,200 degrees Fahrenheit and will resist corrosion from the heat under situations where oxidizing is an issue. This type is also resistant to chipping or flaking under situations where it is cycled through extreme heat and cold temperatures in order to optimize its molecular structure. It does this by forming a dense oxide scale that tightly adheres to its outer layer.

These properties make variant 601 an optimal choice for gas turbines in armed forces applications such as engines for naval vessels and other amphibious ships, patrol boats, destroyers, and aircraft carriers.

Variation 625

Inconel has many uses for armed forces and defense manufacturing applications both on land and in the air. The 625 variation covers the “at sea” element with this metal’s ability to be used in aqueous conditions. Its high strength is created by the addition of niobium which solidifies the matrix of the material. Variation 625 has superb fatigue strength and resists cracking, pitting, and crevice corrosion caused by chloride ions found in seawater. These special features of this metal’s variation make it useful for sea applications such as propeller blades, submarine fittings, submarine propulsion motor elements, and steal-line bellows.

Variation 718

Option 718 is a nickel-chromium alloy that is used in the armed forces and defense sectors because of its creep-rupture strength that is maintained up to a 1,300 degree Fahrenheit level. According to the Center for Nondestructive Evaluation at Iowa State University, creep-rupture is the deformation of the material over time as a load that is under its maximum capacity is applied. Many times extreme temperatures are involved and if the issue is not rectified, the material will ultimately rupture and break.

This variant of Inconel contains sizeable amounts of iron, niobium, and molybdenum, as well as smaller quantities of aluminum and titanium. With its resistance to corrosion, ability to be welded, and to be printed with additive manufacturing capabilities. Incredible strength gives it ideal properties to be used in military applications for turbine engines. Variation 718 is also used in high-speed airframe parts and fasteners that are exposed to high temperatures. This is because of its exceptional tensile and impact properties even when it is under extreme conditions such as exposure to cryogenic temperatures.

Why is Inconel so useful in the manufacturing industry?

Inconel is also part of a group called superalloys. A superalloy is an alloy that exhibits exceptional traits which make them highly useful in industries that need something very strong and resilient. What characteristics make it so useful?

-

- Corrosion resistance to acids such as sulfuric, phosphorus, nitric acids, and hydrochloric acids

- Corrosion resistance to caustic materials, high-purity water, and stress-corrosion cracking

- Retains mechanical properties at extremely high or low temperatures

- Resists pitting, crevice corrosion, oxidation, and inter-crystalline corrosion

- Retains its high strength characteristics, even when heated

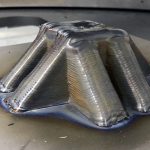

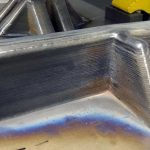

Solid Support Wall

A solid support structure made from Inconel.

Deposition rate: 6 lbs./h

Build time: 7 hours

Material: Inconel 601

Equipment used: ADDere Custom System

Typical Applications for Inconel

Due to Inconel’s ability to remain strong, resist cracking and corrosion, and retain its properties, this metal is found in many aerospace applications. Its resilience also makes it ideal for producing products for the military and defense industries as well.

Military & Defense

Aerospace

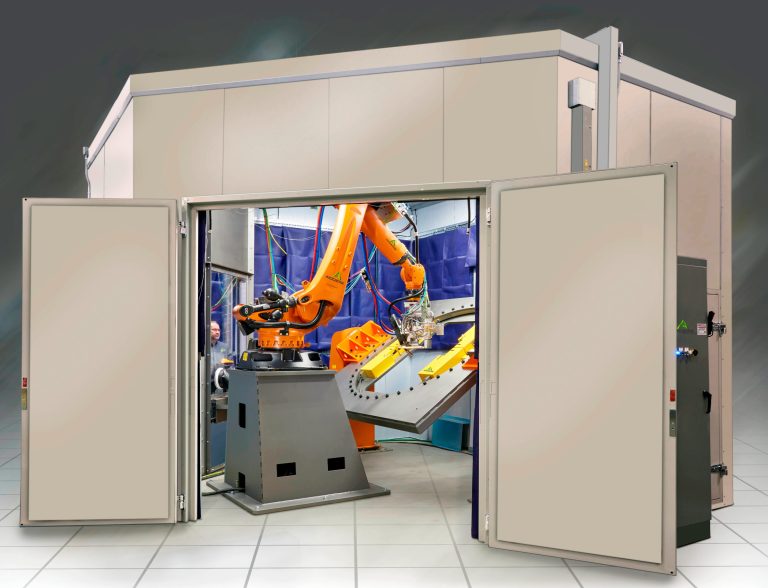

ADDere’s additive manufacturing can streamline the development and production process of large-scale components made from Inconel. Contact us today and see if your manufacturing operations can benefit from ADDere’s additive manufacturing with Inconel.

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Where the ADDere Additive Process Excels Over Metal Casting

Metal casting and additive manufacturing are the two most common methods of producing large-scale metal parts. Metal casting involves pouring molten metal into a mold

Trends and Future Prospects in Large-Scale Metal 3D Printing

Industrial Metal additive manufacturing is not a new technology or concept. Still, it has gained significant momentum in recent years in many industries, thanks to

The Opportunities of Additive Manufacturing for Sustainable Development & Circular Economy

ADDere’s additive manufacturing process contributes to sustainable development and a circular economy by reducing material waste, energy consumption, greenhouse gas emissions and transportation costs. It

How Additive Manufacturing Can Reduce Production Lead Times

Production lead time is a critical variable for companies that rely on production and manufacturing processes to produce goods. In traditional manufacturing processes, it can

ADDere Provides GKN Aerospace with the Industry’s Largest Additive Manufacturing System

Building large-scale titanium parts for aerospace applications requires the largest metal 3D printer available. Because of the demanding nature of aerospace components and their previous

Unlocking Synergies: How Hybrid Manufacturing Can Enhance Additive Manufacturing

Additive manufacturing is a revolutionary technology that enables the creation of complex geometries and customized parts. However, metal additive parts have some limitations, such as