Multi-Material Part Cladding

High-level multi-material cladding ensures part durability

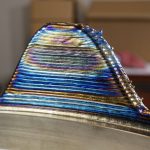

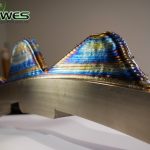

With a variety of metals at its disposal, the ADDere Additive Manufacturing process is a highly versatile laser-wire system that can be used for the application of cladding components with new or different materials. With ADDere’s fine grain control and closed-loop feedback system, overlay welding of materials on parts becomes a highly reliable and repeatable process that offers best-in-class quality.

To control deposition, temperature and location, ADDere’s quality feedback system updates the metal deposition process parameters in essentially real-time. This attention to minute detail in the process allows for the highest levels of cladding quality and performance, making sure a durable and complete wetting of surfaces is achieved.

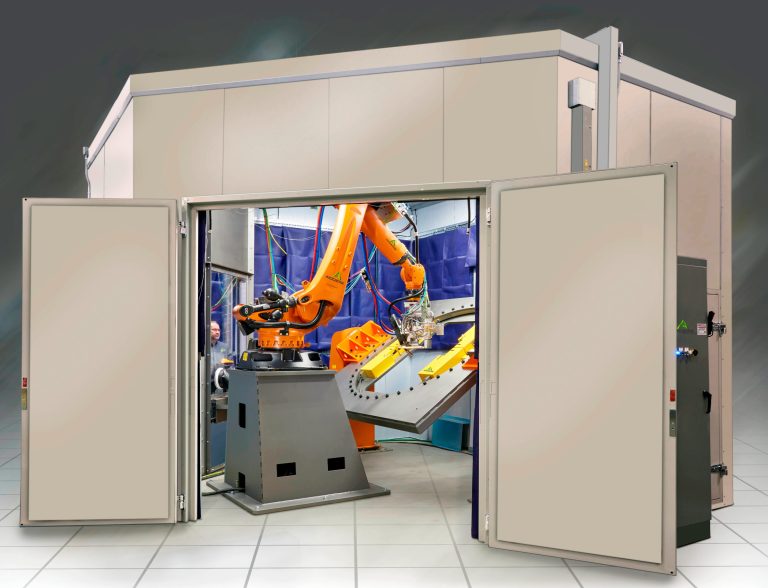

ADDere’s motion system is based on robotic systems that offer some of the greatest abilities in applying overlay welding to shapes beyond simple geometric shapes or applying cladding in simple configurations. While cylinders and tubes are short work, ADDere’s system can provide articulation beyond what conventional gantry systems can provide, allowing the cladding of more complex geometries.

If your business is looking for a fast, cost-effective way to part cladding, please contact us today. The ADDere large-scale additive manufacturing process can print in sizes and materials to fit your business’s needs.

Part Cladding

Evaluation of the part cladding process.

Deposition rate: 5 lbs./h

Build time: 2 hours

Material: Titanium Ti64

Equipment used: ADDere Custom System

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Where the ADDere Additive Process Excels Over Metal Casting

Metal casting and additive manufacturing are the two most common methods of producing large-scale metal parts. Metal casting involves pouring molten metal into a mold

Trends and Future Prospects in Large-Scale Metal 3D Printing

Industrial Metal additive manufacturing is not a new technology or concept. Still, it has gained significant momentum in recent years in many industries, thanks to

The Opportunities of Additive Manufacturing for Sustainable Development & Circular Economy

ADDere’s additive manufacturing process contributes to sustainable development and a circular economy by reducing material waste, energy consumption, greenhouse gas emissions and transportation costs. It

How Additive Manufacturing Can Reduce Production Lead Times

Production lead time is a critical variable for companies that rely on production and manufacturing processes to produce goods. In traditional manufacturing processes, it can

ADDere Provides GKN Aerospace with the Industry’s Largest Additive Manufacturing System

Building large-scale titanium parts for aerospace applications requires the largest metal 3D printer available. Because of the demanding nature of aerospace components and their previous

Unlocking Synergies: How Hybrid Manufacturing Can Enhance Additive Manufacturing

Additive manufacturing is a revolutionary technology that enables the creation of complex geometries and customized parts. However, metal additive parts have some limitations, such as