Visit two of our trusted partners to see ADDere’s latest large-scale 3D metal prints during RAPID+TCT 2019, May 21st-23rd at Cobo Center, Detroit, MI.

Visit Laser Mechanisms Inc. booth 256 to see ADDere’s fully stainless steel airplane. Weighing in at approximately 100 lbs. and 48in long, the plane body was made in Stainless Steel while the wings and tails were in super duplex stainless steel. The total project printing time was 20 hours.

Go to Laser Line Inc. booth 453 to visit ADDere’s 6ftx20in stainless steel propeller blade weighing 170 lbs. The blade features a hollow interior with a .25in the sidewall and is made with little porosity or impurities due to a closed-loop sensor system. From beginning to end, the design took just 30 hours to make using the ADDere system.

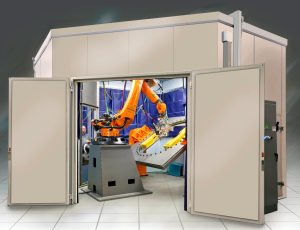

Midwest Engineered Systems developed the ADDere industrial additive manufacturing system in 2017. ADDere is a Laser-Wire Additive manufacturing process with high deposition rates for large parts. With this system, complicated forms can be 3D printed in metal that would otherwise be extremely difficult to create.

Contact us today, for more information on how ADDere can help your business.