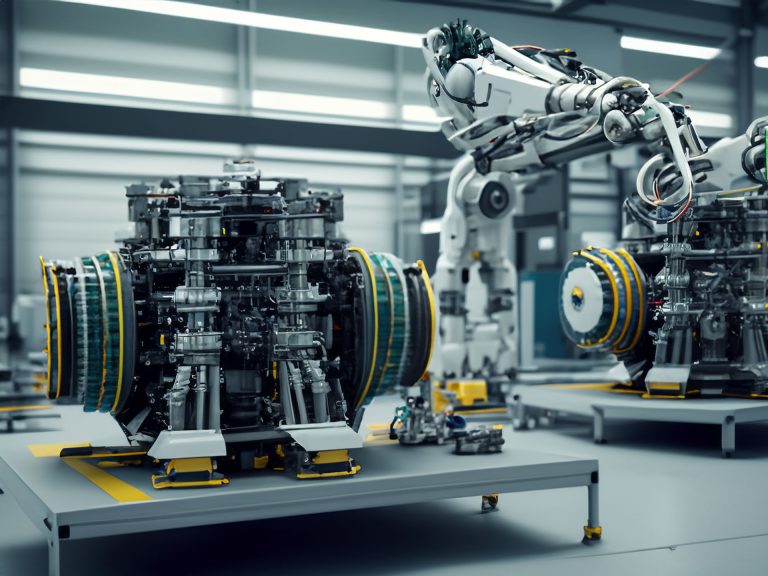

Prototyping & Full-Scale Component Testing

ADDere is perfect for full-scale prototyping

As ADDere prints in a variety of metals including most steel alloys and more exotic materials like titanium and cobalt, it can produce prototypes at large scales making component testing results as close to final requirements as building the part in a conventional production setting.

With ADDere’s laser-wire additive process and closed loop feedback system, prototype parts created meet or exceed the quality found in production castings. The system can virtually guarantee repeatable quality perfect for prototype testing. ADDere allows the ability to sidestep investing in a time-consuming and expensive prototype casting process merely for testing. Parts can now be printed full size in a fraction of the time it would take to have them cast.

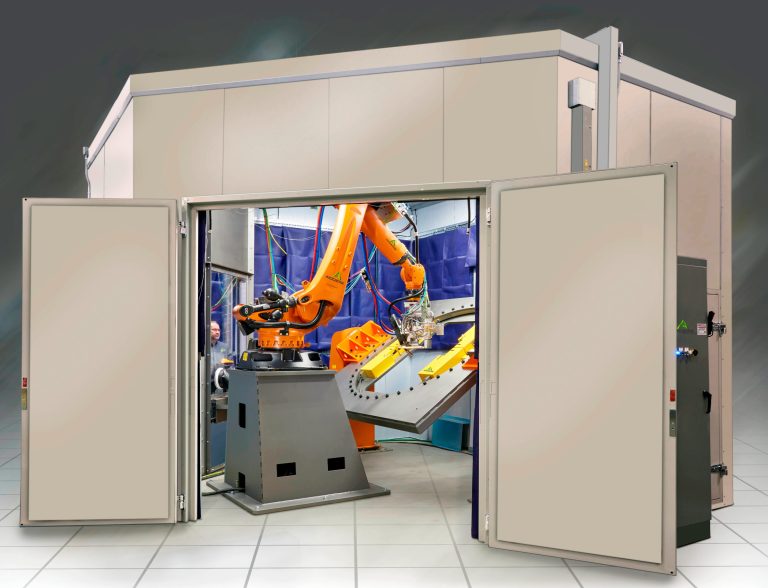

In a variety of ways, the time savings of using ADDere metal additive manufacturing can greatly reduce the component development cycle and get products to market faster. Since ADDere can print in metals at the same grade and size as production castings, these prototype parts can not only be tested for assembly fit but can also be tested in real-world applications to test serviceability. The additively manufactured prototype parts also allow for the honing of production automation operations, allowing manufacturing engineering to develop and test casting finishing processes and make adjustments for manufacturing efficiency to part designs before a single production casting is poured.

If your business is looking for a fast, cost-effective way to full-scale prototyping, please contact us today. The ADDere large-scale additive manufacturing process can print in sizes and materials to fit your business’s needs.

Rocket Thrust Chamber Assembly

Highly complex seamless stainless steel part that stands 42in tall with a wall thickness of 3mm. Learn More ❯

Deposition rate: 4 lbs./h

Build time: 20 hours

Material: Duplex Stainless Steel

Equipment used: ADDere Custom System

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Where the ADDere Additive Process Excels Over Metal Casting

Metal casting and additive manufacturing are the two most common methods of producing large-scale metal parts. Metal casting involves pouring molten metal into a mold

Trends and Future Prospects in Large-Scale Metal 3D Printing

Industrial Metal additive manufacturing is not a new technology or concept. Still, it has gained significant momentum in recent years in many industries, thanks to

The Opportunities of Additive Manufacturing for Sustainable Development & Circular Economy

ADDere’s additive manufacturing process contributes to sustainable development and a circular economy by reducing material waste, energy consumption, greenhouse gas emissions and transportation costs. It

How Additive Manufacturing Can Reduce Production Lead Times

Production lead time is a critical variable for companies that rely on production and manufacturing processes to produce goods. In traditional manufacturing processes, it can

ADDere Provides GKN Aerospace with the Industry’s Largest Additive Manufacturing System

Building large-scale titanium parts for aerospace applications requires the largest metal 3D printer available. Because of the demanding nature of aerospace components and their previous

Unlocking Synergies: How Hybrid Manufacturing Can Enhance Additive Manufacturing

Additive manufacturing is a revolutionary technology that enables the creation of complex geometries and customized parts. However, metal additive parts have some limitations, such as