Engine Intake/Exhaust Guarding

Let ADDere print your

Engine Intake/Exhaust Shielding

Protecting the engine on a front-line military vehicle is nearly as important as protecting the crew. Preventing foreign objects from directly entering the engine through the air intake or the exhaust system while allowing those systems to function correctly requires carefully designed defensive shielding. ADDere’s additive manufacturing process is ideal for producing complete engine guarding with a single solid internal structure that can deflect projectiles and allow consistent airflow.

The ADDere laser wire additive manufacturing system produces 3D printed large-scale, near-net-shape parts in various metals including Titanium, Inconel, Stainless Steel and other superalloys, and most Ferrous-based metals.

ADDere has these additive manufacturing capabilities as well as many more printing capabilities. Contact us today if your business wants 3D-printed stainless steel intake or exhaust shielding.

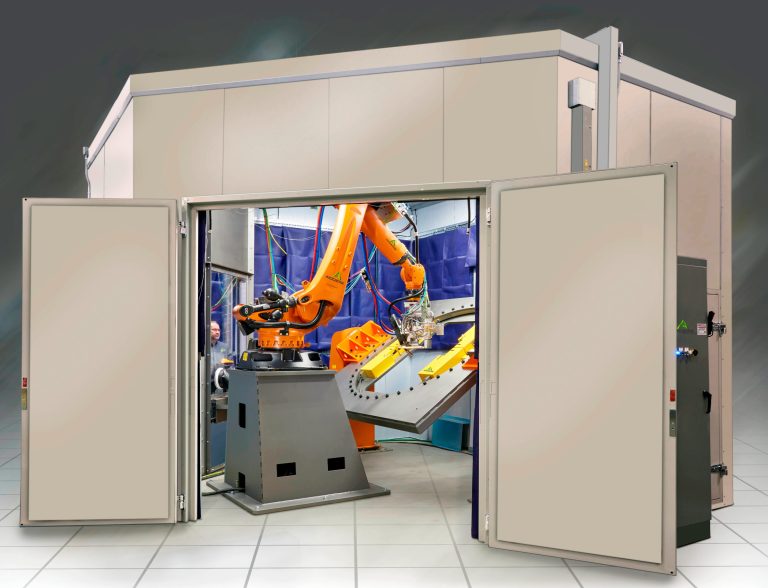

ADDere Print Details

Deposition Rate: 4 lbs. per hour

Total Built Time: 40 hours

Material: Duplex Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

Next Level Industrial-grade Laser Wire Additive Manufacturing

What's going on at ADDere

Latest Blog Posts

ADDere: A Strategic Asset for the Defense Logistics Agency

In the rapidly evolving landscape of defense logistics, metal additive manufacturing has emerged as a pivotal technology, revolutionizing how the Defense Logistics Agency (DLA) operates

Where the ADDere Additive Process Excels Over Metal Casting

Metal casting and additive manufacturing are the two most common methods of producing large-scale metal parts. Metal casting involves pouring molten metal into a mold

Trends and Future Prospects in Large-Scale Metal 3D Printing

Industrial Metal additive manufacturing is not a new technology or concept. Still, it has gained significant momentum in recent years in many industries, thanks to

The Opportunities of Additive Manufacturing for Sustainable Development & Circular Economy

ADDere’s additive manufacturing process contributes to sustainable development and a circular economy by reducing material waste, energy consumption, greenhouse gas emissions and transportation costs. It

How Additive Manufacturing Can Reduce Production Lead Times

Production lead time is a critical variable for companies that rely on production and manufacturing processes to produce goods. In traditional manufacturing processes, it can

ADDere Provides GKN Aerospace with the Industry’s Largest Additive Manufacturing System

Building large-scale titanium parts for aerospace applications requires the largest metal 3D printer available. Because of the demanding nature of aerospace components and their previous