Space Industry

How large-scale 3D metal printing benefits the Aerospace industry

The space and aerospace industries are at the forefront of technological innovation, where precision, efficiency and reliability are not just goals but necessities. ADDere additive manufacturing has become a game-changer in these sectors, offering transformative benefits that are propelling manufacturing to new heights. ADDere’s ability to 3D print in metals like titanium and Inconel – and in large sizes – opens many possibilities for the space and aerospace industries. Processes like multi-stage casting or time-consuming milling can be vastly reduced by using the ADDere laser wire additive manufacturing system. The wire feed metal deposition process can even open up new geometry possibilities.

Unleashing Design Potential

ADDere provides unparalleled freedom in design, allowing engineers to create complex geometries that were previously impossible or too costly to produce with traditional manufacturing methods. This has led to the development of parts with optimized shapes and internal features, such as cooling channels in rocket engines, which enhance performance while reducing weight and material usage. Complex airframe sections can now be combined and printed as one unit, ADDere’s metal printing provides the opportunity to reduce large-scale aerostructure and airframe assembly time. The process also reduces the need for mechanical fastening or bonding needs while removing potential weak points.

Materials that Propel Us Forward

Space vehicle power plant manufacturing also stands to benefit from ADDere additive manufacturing. The ability to increase the number of components made from titanium or Inconel opens the door to higher temperature tolerances and much lower corrosion properties. These attributes are necessary for the harsh environments that space and aerospace engine parts have to perform in. By printing jet and rocket engine components like fan blades, discs, piping and casings, manufacturers can greatly reduce the machining time necessary to finish these precision engine components.

ADDere’s metal additive manufacturing process accelerates the innovation cycle by facilitating rapid prototyping and testing. This allows for quicker validation of designs and materials, ensuring that only the most efficient and reliable components make it to production. The potential for creating more efficient, cost-effective, and sustainable aerospace components is vast, and ADDere is poised to play a central role in the future of aerospace manufacturing.

ADDere's Custom System for Aerospace Applications

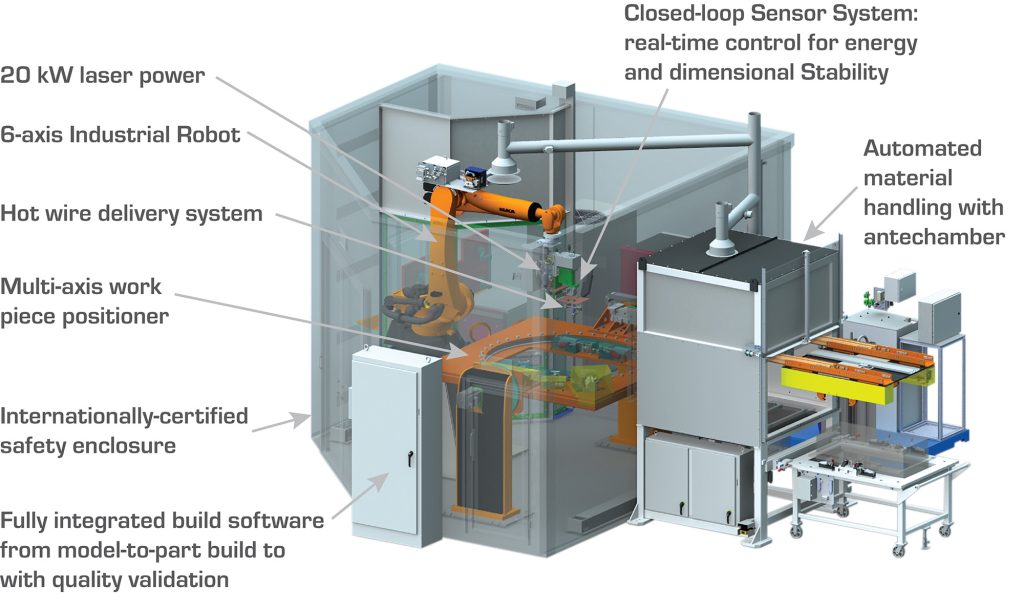

ADDere partnered with GKN Aerospace to install one of our ADDere Custom Systems for large-scale additive manufacturing production at the Oak Ridge National Laboratory (ORNL). GKN’s Cell 2 system uses our additive laser wire metal deposition technology. The system is currently being used to 3D print titanium aircraft components. Features of this ADDere System include a 52 x 32-inch max substrate size, 8-axis of total motion, a sealed inert environment, 20kW laser and the ability for deposition on both sides of the substrate.

This video was produced by GKN Aerospace features a custom built ADDere system.

The ADDere process is ideal for aerospace applications and component construction. We follow strict ITAR compliances in our facilities and processes, which makes us ideal sensitive data handling.

Aerospace components that ADDere can fabricate

Is ADDere right for you?

If your business is looking to manufacture components for the space industry from superalloys in a fast, cost-effective way, then contact us today. The ADDere large-scale laser-wire additive manufacturing process can print in sizes and materials to fit your business’s needs.

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from