Applications

ADDere 3D metal printing offers unlimited possibilities for businesses

ADDere Additive Manufacturing brings to focus a variety of applications where additive printing technology can have an unparallel impact on the way industries approach large-size metal part production. These benefits stem from the technologies that go into ADDere’s products and services that separate it from many of the other competing powder or wire-based additive systems.

ADDere’s ability to 3D print in a variety of metals including stainless steel, Titanium, Inconel and a number of superalloys with quality that meets or exceeds traditional parts casting. Coupled with its production envelope and versatility due to the use of industrial robotics for its movement, ADDere offers a variety of opportunities to take additive manufacturing far beyond what most systems can offer.

If your business is looking to ADDere for one or more of the applications listed above, please contact us today. ADDere’s products and services can 3D print in many sizes and materials that will fit your business’s needs.

ADDere Print Services

Large components operate on their own economies from the high-volume parts made on laser-wire machines. Buying a large-scale additive manufacturing system without testing its abilities can feel like a gamble, especially when there are specialized requirements for the parts to be printed. Sometimes the number of components needed isn’t enough to rationalize the purchase of hardware needed to print the smaller runs. Many times it’s both.

In either case, ADDere understands the situation and provides metal printing as a service to manufacture these components on our machines. Whether to prove our system’s metal additive manufacturing abilities or to run parts without having to invest in 3D printing systems and training, ADDere can print your projects. Learn More…

do you want to learn more about ADDere's products and services?

Best-in-class Printing Performance

Sample Parts

Rocket Thrust Chamber

Deposition Rate: 4 lbs. per hour

Total Built Time: 20 hours

Material: Duplex Stainless Steel

Dimensions: 1 meter tall and 1 meter wide

System Used: ADDere Custom System

The final machined thrust chamber body has a sidewall thickness of 3mm with thicker walls in the combustion chamber.

Engine Exhaust/Intake Guarding

Deposition Rate: 4 lbs. per hour

Total Built Time: 40 hours

Material: Duplex Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

A complex part made from stainless steel. This part was built as a single solid component.

Turbine Blade

Deposition Rate: 4.5 lbs. per hour

Total Built Time: 30 hours

Material: Duplex Stainless Steel

Dimensions: 1.8 meters tall

System Used: ADDere Custom System

The completed turbine blade has a hollow interior and a 5mm wide sidewall. It is 1800 layers tall with a height variant of 0.5mm.

Propeller

Deposition Rate: 3 lbs. per hour

Total Built Time: 4 hours

Material: Carbon Steel

Dimensions: Each blade is 25 cm long

System Used: ADDere Standard System

Thin-walled metal components are 3D printed directly onto an existing steel part in this case a piece of steel round bar.

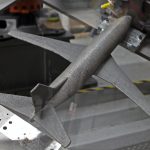

Freeform Design

Deposition Rate: 4.5 lbs. per hour

Total Built Time: 20 hours

Material: Stainless Steel

Dimensions: Wingspan is 1.6 meters long

System Used: ADDere Custom System

A large demonstration part with a hollow 6mm wall thickness.

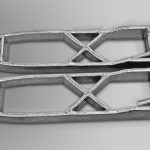

Wing Spar Cross-section

Deposition Rate: 6 lbs. per hour

Total Built Time: 1 hour

Material: Titanium Ti64

Dimensions: 50 cm long

System Used: ADDere Custom System

High-complexity 3D print in titanium. Cross-section aspects of 3D printing reduce construction times and make for a stronger overall part.

Thin Wall Curved Pipe

Deposition Rate: 6 lbs. per hour

Total Built Time: 3 hours

Material: Stainless Steet

Dimensions: 22 cm tall

System Used: ADDere Standard System

Custom-designed thin 4mm wall pipe that can be produced in different shapes and angles.

Fan Fins Assembly

Deposition Rate: 4 lbs. per hour

Total Built Time: 13 hours

Material: Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

Custom-designed fan fin assembly with a hollow core.

Large Gear

Deposition Rate: 20 lbs. per hour

Total Built Time: 10 hours

Material: Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

A custom-designed solid gear or sprocket made entirely from stainless steel.

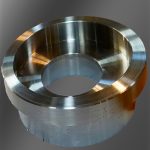

Mold Die Form

Deposition Rate: 6 lbs. per hour

Total Built Time: 3 hours

Material: Carbon Steel

Dimensions: 25 cm diameter

System Used: ADDere Standard System

Rapidly produce custom plastic injection molding die forms with additive manufacturing.

From common metals to superalloys

Materials ADDere Prints

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from