ADDere Runtime Software

The best-in-class software that drives additive manufacturing

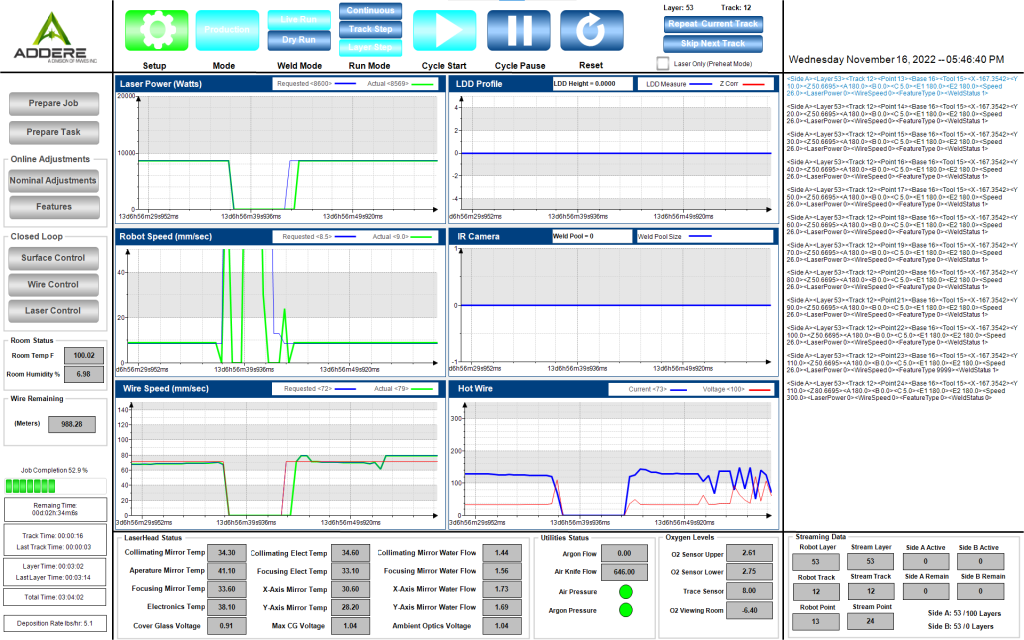

The ADDere Runtime Software gives the user a complete runtime interface to the 3D additive manufacturing process. Simply put the ADDere Runtime Software coordinates communications to all the additive subsystems and operations.

The ADDere runtime system delivers the geometric source file to a specific motion device. The embedded wire feed rate, hot wire control, laser power, laser spot size and print speed coordinate with the geometric motion. With ADDere, the optional runtime sensor data from the laser profiler, infrared camera, hot wire system and/or part view IR camera can be used as real-time feedback. Custom process-specific algorithms can be created in the ADDere software to affect the build process.

The controlling characteristics of the ADDere Runtime Software are extensive and adapting. The software controls the build height and width, the energy density control, head mapping and inter-pass print control, and the deposition rate control. All of which can be accomplished with the ADDere Custom Feedback Algorithm Control System.

Dynamic High-Resolution Height Control

One of the biggest problems of traditional 3D metal additive manufacturing systems is that the 3D geometric slice file must be processed before the part is printed. This means that the print track properties must be very accurate to build relativity large parts. The ADDere system uses proprietary technology to create geometric source files with high resolution. The track properties are entered directly into the ADDere Runtime Software. Using the sensor feedback the ADDere software AI determines the height of the next layer keeping the build geometrically accurate.

Lights Out Manufacturing and Problem Recognition

- Room temperature and humidity

- Purity of the inert gas system

- Cleanliness and Integrity of the optics

- The integrity of the laser

- The integrity of the cooling system

- The integrity of the wire feeder system

- The integrity of the hot wire system

- The integrity of the safety system

- The integrity of the specific build process using the ADDere sensor array

The ability of the ADDere AI to monitor and affect these systems allows the system to be run for long periods of time in an unmonitored state.

ADDere System Software Features

Features of the ADDere software are extensive. The following represent the key features that set ADDere’s software apart from other additive manufacturing programs.

Equipment coordination and synchronization

The ADDere software platform provides all hardware and sensor coordination and synchronization for the printing process.

Loading and processing a source (.src) file

The ability to load and process a source (.src) file of a sliced part. The software allows for newly sliced or previously printed parts to be loaded and processed for printing.

Teaching the system where to place the part on the substrate

The ADDere system allows the user to specify where on a substrate the printed part is to be located. The ability to dry run the system is also provided to ensure proper clearances and orientation.

Preheating the substrate before a build

The ADDere system has the ability to run the first layer of the printing process at a reduced laser setting. The first layer can be run a discrete number of times or the preheating process can be tied back to an optional IR camera system for closed-loop control.

Process for Printing the Part

The ADDere software is used to facilitate, control and monitor the entire printing process.

Realtime video of the additive process

Monitoring the build quality in real-time

The ADDere software platform allows the user to monitor critical parameters and processes during the build process. ADDere has the ability to monitor:

-

- Current layer, track and point

- Estimated and current print time

- Commanded and actual laser power

- Commanded and actual wire speed

- Commanded and actual linear print speed

- Hot wire current and voltage

- Expected and actual part height

- High-Definition (HD) process video

- Weld pool characteristics

Creating custom control algorithms to affect the build in real-time

The ADDere software allows the operator to create custom control algorithms. The process parameters consist of hot wire current/voltage, actual measured print height and control of the weld pool size. These parameters can then control various attributes of the build process. Such as the wire speed, linear print speed, laser power, print height offset and track height offset.

The system operator can make changes on the fly

The ADDere software allows the operator to make discrete on the fly changes to the 3D printing process. The printing characteristics that the operator can change is the print head height offset, the wire-speed offset, the laser setpoint offset, the print speed offset, the track height (high Z-resolution mode), skip/repeat track and algorithm changes.

The ADDere System AI can make changes on the fly

The ADDere system AI can automatically make discrete on the fly changes to the 3D printing process. The printing characteristics that the software AI can control is the print head height offset, the wire-speed offset, the laser setpoint offset, the print speed offset and the track height (high Z-resolution mode).

Stopping and restarting the build process

The ADDere software provides the operator the ability to print in the following modes:

-

- Track Step – Stop after each track and require a manual restart

- Layer Step – Stop after each layer and require a manual restart

- Continuous – Print continuously until stopped by the operator or the system.

The ADDere system also allows the operator to restart the print process from any layer, Track and Point in the print file.

Real-time recording of the build process and data collection

The ADDere software system allows the user to capture the actual print process so it can be duplicated. The system also allows the user to capture in-process data at the rate of 1kHz. Over 98 real-time process parameters as fast as 1ms periods can be saved during the build process.

If you have any questions about the ADDere Runtime Software and its capabilities, please feel free to reach out to us.

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from