Engine Intake/Exhaust Guarding

Let ADDere print your

Engine Intake/Exhaust Shielding

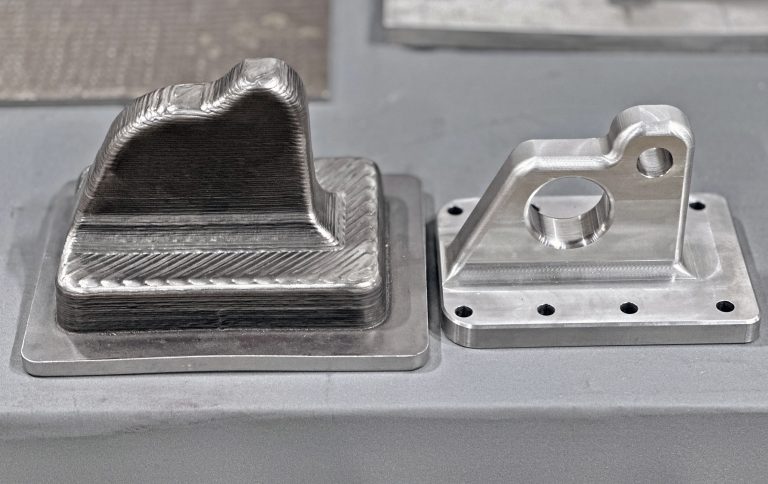

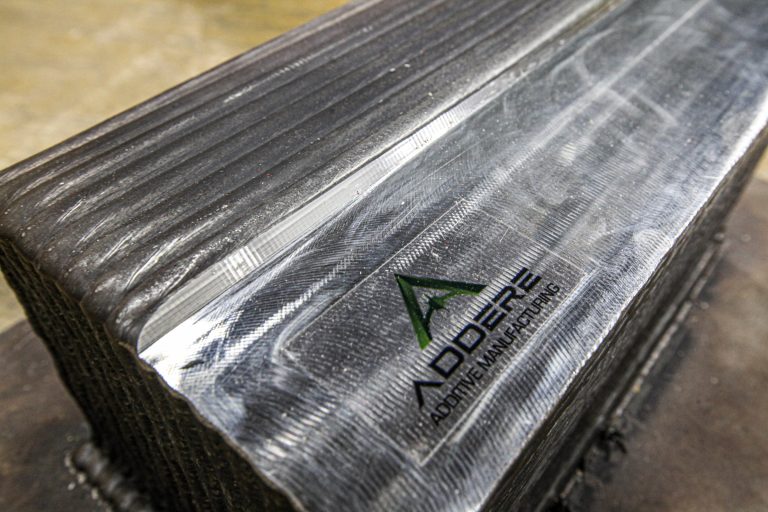

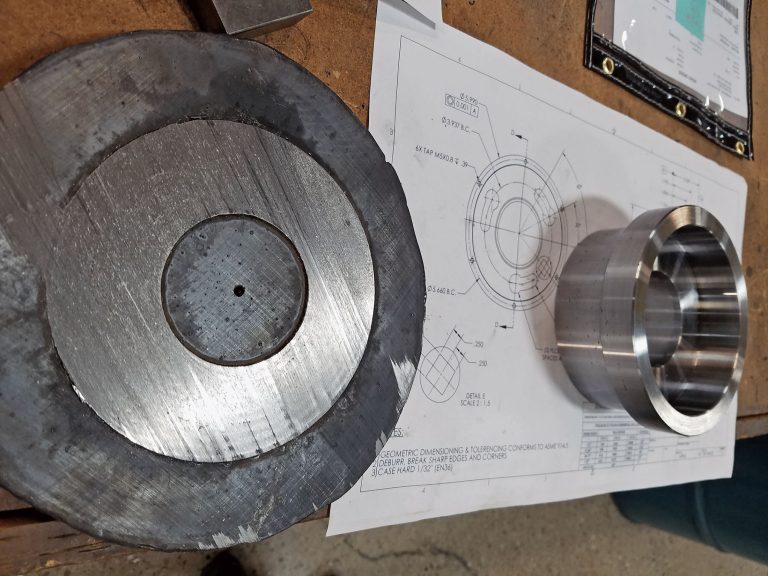

Protecting the engine on a front-line military vehicle is nearly as important as protecting the crew. Preventing foreign objects from directly entering the engine through the air intake or the exhaust system while allowing those systems to function correctly requires carefully designed defensive shielding. ADDere’s additive manufacturing process is ideal for producing complete engine guarding with a single solid internal structure that can deflect projectiles and allow consistent airflow.

The ADDere laser wire additive manufacturing system produces 3D printed large-scale, near-net-shape parts in various metals including Titanium, Inconel, Stainless Steel and other superalloys, and most Ferrous-based metals.

ADDere has these additive manufacturing capabilities as well as many more printing capabilities. Contact us today if your business wants 3D-printed stainless steel intake or exhaust shielding.

ADDere Print Details

Deposition Rate: 4 lbs. per hour

Total Built Time: 40 hours

Material: Duplex Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

Next Level Industrial-grade Laser Wire Additive Manufacturing

What's going on at ADDere

Latest Blog Posts

Join Us at FABTECH 2024 in Orlando on October 15-17

ADDere will be showcasing the new ADDere Small Format additive system at our partner Laser Mechanisms booth (#W3029) at this year’s FABTECH in Orlando, FL

3D Printing Metal Structural Components On Demand

Metal structural hardpoints are critical components where significant loads and stresses are concentrated in a vehicle’s frame or body. These include mounting fixturing, tow/lift points,

How to Ensure Quality Control & Traceability in Your Printed Parts

The ADDere laser-wire additive manufacturing process creates complex metal parts by depositing layers of metal wire on a build plate. This process offers many advantages

Manage Your Inventory Efficiently with Additive Manufacturing

Inventory management is a critical aspect of any manufacturing company, where the balance between minimizing stock and ensuring the availability of materials can significantly impact

ADDere Introduces a New Additive System

ADDere is expanding its capabilities by introducing a small format additive system that complements our other two large-scale laser-wire additive systems. The new ADDere system

Life Cycle Management for Additive Manufacturing Automation Systems

ADDere’s additive manufacturing process has many advantages over conventional manufacturing methods, such as reducing material waste, increasing design flexibility, new part functionalities and unique material