One of the most important factors to consider when planning an ADDere laser-wire 3D printing project is the choice of metal alloy. Different metal alloys have different properties, such as density, hardness, corrosion resistance, thermal conductivity and melting point. These properties affect the printability, performance, and application of the final part. Therefore, choosing the right metal alloy for your project is crucial to ensure the quality and functionality of your 3D printed part.

We have compiled several guidelines on how to choose the right metal alloy based on a number of factors for your 3D printing project.

What to consider when choosing a metal alloy for 3D printing

There are several factors to consider when choosing a metal alloy when specing out your part.

Design and Geometry

The design and geometry of your part will determine the level of detail, complexity, and accuracy that you need from your metal 3D printer. Some metal alloys are more suitable for fine details and intricate shapes than others. For example, stainless steel and titanium are more ductile and can produce smoother surfaces than aluminum. The design and geometry of your part will also affect the amount of support structures and post-processing that you will need to remove them. Learn more about the design limitations.

Mechanical and Physical Properties

The mechanical and physical properties of your part will determine the strength, durability, and performance that you need from your metal alloy. Some metal alloys are more resistant to stress, fatigue, wear, and corrosion than others. For example, titanium and nickel alloys are more suitable for high-temperature and high-pressure applications than aluminum or steel. The mechanical and physical properties of your part will also affect the weight, density, and thermal conductivity of your metal alloy.

Cost and Availability

The cost and availability of the metal alloy will determine the feasibility and affordability of your additive printing project. Some metal alloys are more expensive and scarce than others. For example, nickel-based wire spools of Inconel and titanium can run from $50 to $100 a pound and are far more costly and rare than stainless steel or aluminum which can run $10 to $25 a pound. The cost and availability of your metal alloy will also affect the environmental impact and sustainability of your additive project.

Commonly used metal alloys for 3D printing

Virtually any metal alloy that can be acquired in welding wire form is suitable for additive manufacturing. Some of the more common alloys ADDere works in are:

Stainless Steel

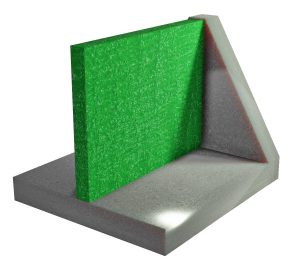

Stainless steel is a versatile and affordable metal alloy that can be used for a variety of applications. Stainless steel has good corrosion resistance, strength, and ductility. It can produce smooth and detailed parts with minimal post-processing. Stainless steel has low thermal conductivity and high density, which can affect the cooling and weight of the part.

Titanium

Titanium is a lightweight and strong metal alloy that can be used for high-performance and biomedical applications. Titanium has excellent corrosion resistance, fatigue resistance, and biocompatibility. It can produce parts with complex geometries and thin walls. Titanium has a high melting point and low thermal conductivity, which can make it difficult to print and require high-energy input.

Aluminum

Aluminum is a light and cheap metal alloy that can be used for aerospace and automotive applications. Aluminum has good thermal conductivity, electrical conductivity, and machinability. It can produce parts with low weight and high stiffness. Aluminum has a low melting point and high thermal expansion, which can cause warping and cracking during printing and cooling.

Nickel-Based Alloys

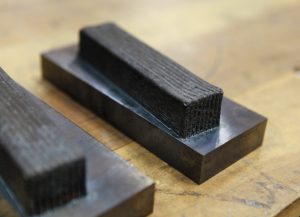

Nickel-based alloys and superalloys, such as Inconel and Hastelloy, are durable and resistant metal alloys that can be used for extreme environments and applications. Nickel has high corrosion resistance, temperature resistance, and pressure resistance. It can produce parts that can withstand harsh conditions such as high temperatures, high pressure, or corrosive media. Nickel has high density and high cost, which can limit its use for large-scale projects.

Additive manufacturing is a rapidly expanding field that offers many advantages over traditional manufacturing methods. ADDere’s additive manufacturing process can produce complex geometries, reduce material waste, and create functional parts with high strength and durability.

If you are looking to produce your own parts or would like us to run off a small number of parts, then contact us today and get a quote for a complete ADDere system or utilize our in-house print services. We can also discuss your build and provide advice on optimizing it to get the best possible results.